Digital Dentures

Digital dentures are an advanced type of removable dental prosthetic designed to replace missing teeth. Unlike traditional dentures, which rely on manual processes and molds, digital dentures are designed and manufactured using state-of-the-art digital technology.

Features of Digital Dentures in Plano, TX

State-of-the-art technology for Better Fit and Aesthetics

One of the most significant advantages of digital dentures is the use of state-of-the-art technology to create a retentive and comfortable fit. Traditional dentures are often prone to shifting or slipping, causing discomfort and affecting the wearer's ability to eat, speak, or smile confidently. In contrast, digital dentures are designed to provide a more secure fit thanks to precise digital impressions and the accuracy of 3D printing technology.

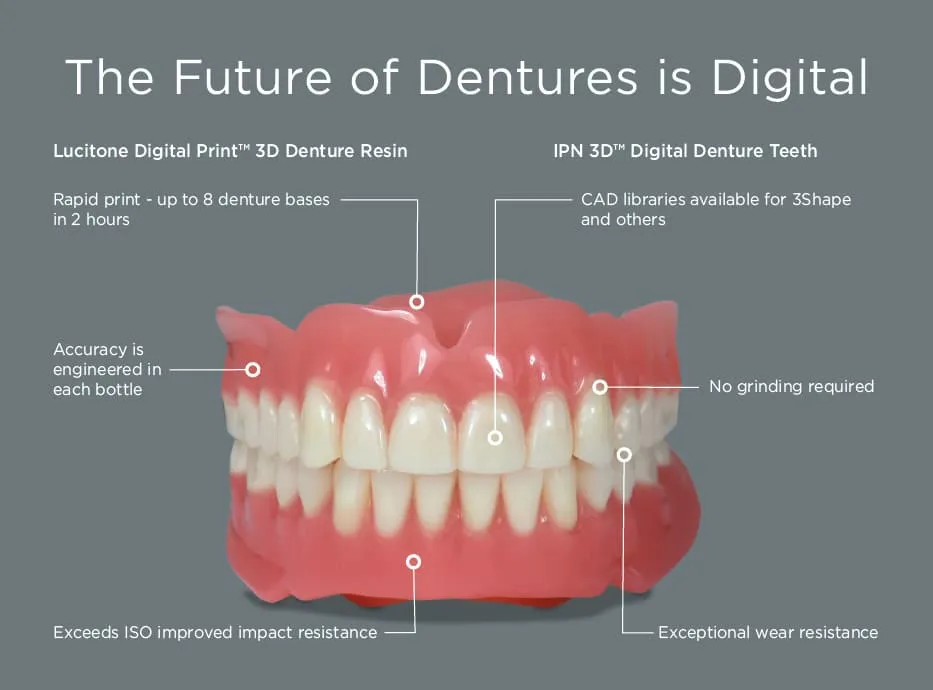

The materials used in digital dentures also contribute to a much more natural look and feel. For example, the Lucitone Digital Print 3D Denture resin is a high-quality material used in digital denture production. This resin offers exceptional strength and durability while also being lightweight and comfortable to wear. It is engineered for superior aesthetics, closely mimicking the appearance of natural gum tissue.

IPN 3D Digital Denture Teeth are advanced, 3D-printed teeth designed for use in digital dentures. Made from an Interpenetrating Polymer Network (IPN) material, they offer a highly durable, wear-resistant, and natural-looking solution for patients needing dentures. These teeth are customized using digital technology, providing a precise fit and lifelike appearance with enhanced comfort and functionality. Their superior aesthetics and durability make them an ideal choice for creating long-lasting, comfortable dentures that blend seamlessly with a patient’s natural smile.

Rapid Production and Customization

Digital dentures are not only more accurate, but they also significantly reduce the time required to produce them. Traditional dentures often require multiple appointments, fittings, and adjustments, which can be time-consuming and frustrating for patients. In contrast, digital dentures can be created more quickly, with some systems allowing up to 8 denture bases to be printed in just 2 hours. This rapid production means that patients can receive their custom dentures in a much shorter time frame, reducing the waiting time and the need for multiple fittings.

Digital technology also allows for greater customization of dentures. CAD libraries are available for 3Shape and other systems, making it easier to design dentures that are tailored to the unique needs of each patient. These libraries contain pre-designed templates for various dental structures, helping dental professionals create a denture that fits perfectly and functions well for the patient's specific oral anatomy. Whether the patient requires a full set of dentures or partials, digital dentures can be customized with greater precision than traditional methods.

Engineered for Accuracy and Comfort

One of the most important benefits of digital dentures is their accuracy. Traditional dentures are typically created by taking physical impressions of the mouth, a process that can lead to slight distortions or errors in fit. With digital dentures, the entire process is digitized, from scanning the mouth to designing the prosthetic.The use of precise digital tools eliminates many of the potential errors associated with manual processes, ensuring that the denture fits as comfortably as possible.

Additionally, no grinding is required with digital dentures, as the system's precision ensures that the denture is built to exact specifications. This eliminates the need for adjustments and grinding, which are often necessary with traditional dentures. As a result, digital dentures provide a more comfortable experience for the patient from the outset.

The accuracy of digital dentures is further enhanced by the fact that the process is engineered in each bottle of material used. This ensures consistent quality and performance in every denture produced, giving patients the peace of mind that their prosthetic is of the highest possible standard.

Durability and Resistance

Digital dentures are also designed to be more durable than their traditional counterparts. The materials used in digital dentures, such as Lucitone Digital Print resin, exceed ISO standards for improved impact resistance, meaning that the dentures are less likely to break or chip under normal usage. This increased durability contributes to the long-term effectiveness and longevity of the dentures, providing a better value for patients.

In addition to impact resistance, digital dentures offer exceptional wear resistance. Traditional dentures may wear down over time, losing their original shape and functionality. However, the advanced materials used in digital dentures are engineered to withstand everyday wear and tear, maintaining their integrity and appearance for a much longerperiod. Call us to learn more.

Digital Dentures in Plano, TX - Process

The process of getting digital dentures involves several key steps, leveraging advanced technology for a more precise and efficient experience. Here's a brief overview:

Initial Consultation

The process begins with a consultation where your dentist will assess your oral health and discuss your specific needs for dentures, including whether you need full or partial dentures.

3D Scanning

Instead of using traditional molds, the dentist will take a 3D scan of your mouth using a specialized intraoral scanner. This creates a detailed digital model of your dental structure, ensuring a more accurate fit compared to traditional impressions.

Digital Design

The digital scan is sent to a computer-aided design (CAD) system, where the denture is customized based on your unique mouth structure. CAD libraries may be used to help design the prosthetic, ensuring a personalized fit.

Material Selection

Advanced materials like Lucitone Digital Print resin and IPN 3D Digital Denture Teeth are chosen for the denture based on strength, durability, and aesthetic appeal.

3D Printing or Milling

The final design is sent to a 3D printer or milling machine that fabricates the denture. This process is faster and more precise than traditional denture fabrication, and the denture is ready in a shorter time frame.

Fitting and Adjustments

Once the dentures are produced, you'll return to the dentist for a fitting. The digital process ensures an accurate fit, but minor adjustments may be needed for comfort.

Final Denture

After adjustments, your digital dentures are ready for use. These dentures provide a secure, comfortable fit and improved aesthetics compared to traditional dentures.

This process is generally quicker and more precise than the conventional method, offering patients a better overall experience.

Conclusion

Digital dentures represent a significant leap forward in the world of prosthetic dentistry. Thanks to state-of-the-art technology, these dentures offer a better fit, increased comfort, and improved aesthetics compared to traditional options. With the use of advanced materials like Lucitone Digital Print 3D Denture resin and IPN 3D Digital Denture Teeth, patients can enjoy dentures that look and feel more natural than ever before.

Moreover, the rapid production capabilities and enhanced customization options make digital dentures a more convenient and efficient solution for patients seeking a high-quality dental prosthetic. With precision engineering and superior durability, digital dentures are a long-lasting investment in both function and appearance.

For patients seeking a modern solution to missing teeth, digital dentures provide a revolutionary option that addresses the limitations of traditional dentures, offering a more comfortable, natural, and aesthetically pleasing alternative. To learn more about digital dentures, visit All Day Smiles Dental at 3020 LEGACY DRIVE, SUITE 210, PLANO, TX 75023, or call 972-433-7933.

Office Hours

MON9:00 am - 5:00 pm

TUE9:00 am - 5:00 pm

WED9:00 am - 5:00 pm

THU9:00 am - 5:00 pm

FRI9:00 am - 5:00 pm

SAT9:00 am - 2:00 pm

SUNClosed